Page 59 - EQTips_Eng

P. 59

IITK-BMTPC Earthquake Tip 29

What are the Essential Features of Confined Masonry Houses? page 2

beams above and below it. Earthquake behaviour In tie-columns, at least 4 deformed steel bars of 10

improves with the number of fully-confined masonry mm diameter should be provided, and tied with 6 mm

walls. For good earthquake behavior, at least a diameter mild steel ties at 200 mm centers (Figure 6a);

reasonable wall density should be available of fully closely spaced ties are required in top and bottom

confined masonry (as a percentage of plinth area of the portion of a tie-column, with spacing of 100 mm. Ties

building) in each plan direction of the building; this should have 135° hook ends. In RC tie-beams,

depends on a number of factors including the expected minimum reinforcement to be provided is somewhat

ground acceleration, number of storeys, and masonry similar.

compressive and shear strength. This reasonable wall Constructional Guidelines

density varies from 2% to 5%. Minimum depth Using quality materials, ensuring good workmanship

(height) of RC plinth beams should be 300 mm. and faithfully implementing architectural and structural

Many options have been practiced with regard to guidelines are vital in construction of CM buildings. For

foundations of CM houses, namely RC tie-column improved earthquake performance, the interface

starts from (1) plinth beam (house has no foundation between masonry walls and tie-columns should be

beam), (2) foundation beam (house has plinth beam), toothed, i.e., bricks of masonry courses are staggered at

and (3) foundation PCC (house has no foundation the interface with tie-columns (Figure 5a). This ensures

beam, but plinth beam is used). Option (3) is used that masonry walls are held snugly between tie-

commonly (Figure 4). columns. Toothing should be such that the minimum

gap from bars of tie-column is 25mm to the nearest

RC Slab

Slab reinforcement brick face and 75mm to the farthest brick face.

not shown Maximum vertical lift per day of masonry walls

should be 1.2 m. And, concrete for the tie-columns

should be poured before the next lift of 1.2 m of

masonry wall is built. This ensures that concrete in tie-

Floor columns is reasonably compacted, especially when it is

Plinth Level Plinth hand compacted.

Beam Beam

The formwork is butted against the masonry wall

PCC of segment for pouring concrete in tie-columns of CM

Foundation construction. This is the main strength of this

construction – snug fit between masonry walls and

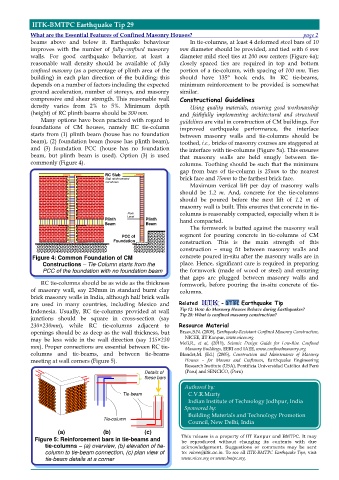

Figure 4: Common Foundation of CM concrete poured in-situ after the masonry walls are in

Constructions – Tie-Column starts from the place. Hence, significant care is required in preparing

PCC of the foundation with no foundation beam the formwork (made of wood or steel) and ensuring

that gaps are plugged between masonry walls and

RC tie-columns should be as wide as the thickness formwork, before pouring the in-situ concrete of tie-

of masonry wall, say 230mm in standard burnt clay columns.

brick masonry walls in India, although half brick walls

are used in many countries, including Mexico and Related - Earthquake Tip

Indonesia. Usually, RC tie-columns provided at wall Tip 12: How do Masonry Houses Behave during Earthquakes?

Tip 28: What is confined masonry construction?

junctions should be square in cross-section (say

230×230mm), while RC tie-columns adjacent to Resource Material

openings should be as deep as the wall thickness, but Brzev,S.N. (2008), Earthquake-Resistant Confined Masonry Construction,

NICEE, IIT Kanpur, www.nicee.org

may be less wide in the wall direction (say 115×230

Meli,R., et al, (2011), Seismic Design Guide for Low-Rise Confined

mm). Proper connections are essential between RC tie-

Masonry Buildings, EERI and IAEE, www.confinedmasonry.org

columns and tie-beams, and between tie-beams Blondet,M. (Ed.) (2005), Construction and Maintenance of Masonry

meeting at wall corners (Figure 5). Houses – for Masons and Craftsmen, Earthquake Engineering

Research Institute (USA), Pontificia Universidad Católica del Perú

(Peru) and SENCICO, (Peru)

Details of

these bars

Authored by:

Tie-beam C.V.R.Murty

Indian Institute of Technology Jodhpur, India

Sponsored by:

Tie-column Building Materials and Technology Promotion

Council, New Delhi, India

(a) (b) (c)

This release is a property of IIT Kanpur and BMTPC. It may

Figure 5: Reinforcement bars in tie-beams and be reproduced without changing its contents with due

tie-columns – (a) overview, (b) elevation of tie- acknowledgement. Suggestions or comments may be sent

column to tie-beam connection, (c) plan view of to: nicee@iitk.ac.in. To see all IITK-BMTPC Earthquake Tips, visit

tie-beam details at a corner www.nicee.org or www.bmtpc.org.